Understanding Diamond Abrasive Filament in Nylon Brushes: A Guide to Types, Features, and Applications

As someone keen on advanced manufacturing, I've always been fascinated by materials that combine strength and flexibility. Today, I want to share insights into a remarkable innovation: diamond abrasive filament in nylon brushes. These specialized brushes merge the toughness of diamonds with the adaptability of nylon, offering superior solutions for polishing and deburring across various industries. Let's delve into what makes them so effective. This guide will explore the types, features, and applications of these powerful tools, highlighting how diamond abrasive filament technology is revolutionizing surface finishing.

Key Takeaways

- Core Composition: Diamond abrasive filaments are a composite material combining the super-hardness of diamond particles with the flexible, durable, and chemical-resistant properties of nylon polymers, typically Nylon 6, 610, or 612.

- Superior Performance: Due to diamond's unparalleled hardness, these brushes provide faster, more consistent cutting action and a longer lifespan compared to traditional abrasives like Silicon Carbide or Aluminum Oxide.

- Versatile Applications: They are essential for precision tasks on hard materials, including deburring carbide tools, polishing ceramics and glass, and finishing aerospace alloys. They are also used for creating aesthetic finishes on stone and for general surface preparation in automotive and other industries.

- Selection Criteria: Choosing the right brush involves considering the workpiece material, the desired finish, grit size, filament diameter, and operating parameters like speed and pressure to ensure optimal performance and longevity.

Understanding the Engineering of Diamond Abrasive Filament

The effectiveness of a diamond abrasive brush isn't just about the materials used; it's about the sophisticated engineering that brings them together. Creating a filament that is both incredibly aggressive and remarkably flexible is a feat of material science. This process involves a deep understanding of polymer chemistry and abrasive technology to produce a tool that can withstand rigorous industrial use while delivering consistent, high-quality results. The synergy between the diamond abrasive and the nylon carrier is the key to its unique performance, allowing it to solve complex surface finishing challenges that other tools cannot.

The Core Components: Nylon and Diamond Abrasive Filament

At the heart of these advanced tools are two materials that seem like opposites: the hardest substance known to man and a flexible, resilient polymer. It is the precise combination of these components that unlocks their powerful capabilities. The nylon acts as the backbone, providing the essential flexibility and durability, while the diamond particles serve as the cutting agents, delivering unmatched abrasive power.

Nylon's Role: Flexibility and Durability

Nylon is not just a simple plastic carrier; it is a critical component that defines the brush's performance. The most commonly used types in high-performance abrasive filaments are Nylon 6, Nylon 610, and particularly Nylon 612, chosen for their specific mechanical and chemical properties.

- Flexibility and Shape Memory: Nylon's inherent flexibility allows the filaments to conform to complex, irregular, and contoured surfaces. This ensures that the abrasive particles maintain optimal contact with the workpiece, even in hard-to-reach areas. Furthermore, nylon possesses excellent "bend recovery" or shape memory. After being flexed during operation, the filaments return to their original straight position, ensuring consistent performance and preventing the brush from "flagging" or losing its shape over time.

- Durability and Wear Resistance: The polymer base is engineered for high fatigue resistance. It can withstand millions of flex cycles without breaking, which directly contributes to the brush's long operational life. This durability means fewer brush changes, reduced machine downtime, and lower overall tooling costs.

- Moisture and Chemical Resistance: High-grade nylons like Nylon 612 exhibit low moisture absorption rates. This is crucial because absorbed moisture can soften the filament and reduce its stiffness and cutting efficiency. Additionally, these nylons are resistant to a wide range of oils, coolants, and chemical solvents commonly used in industrial machining environments, ensuring the filament's integrity is not compromised during wet operations.

Diamond's Contribution: Unmatched Hardness and Cutting Power

While nylon provides the delivery system, the diamond particles do the actual work. Diamond is the ultimate abrasive, and its integration into the filament is what elevates these brushes to a high-performance category.

- Exceptional Hardness: With a score of 10 on the Mohs hardness scale, diamond is the hardest known natural material. This allows it to easily cut, grind, and polish extremely hard materials like tungsten carbide, ceramics, hardened steels, and exotic aerospace alloys. Unlike softer abrasives that can dull quickly against these materials, diamond maintains its sharp cutting edges for a prolonged period.

- High Thermal Conductivity: Diamond has exceptional thermal conductivity. This property helps to dissipate heat generated at the point of contact between the abrasive and the workpiece. By drawing heat away from the cutting zone and into the nylon filament and coolant, it reduces the risk of thermal damage to sensitive workpieces and prolongs the life of the nylon carrier.

- Consistent and Precise Cutting: The diamond particles embedded in the filament act like microscopic cutting tools. As the nylon carrier wears away slowly over time, new, sharp diamond particles are constantly exposed at the filament's tip. This self-sharpening mechanism ensures a consistent material removal rate and surface finish quality throughout the brush's entire lifespan, a feature that is difficult to achieve with conventional bonded abrasive tools. The result is a highly predictable and repeatable finishing process, which is critical for quality control in precision manufacturing.

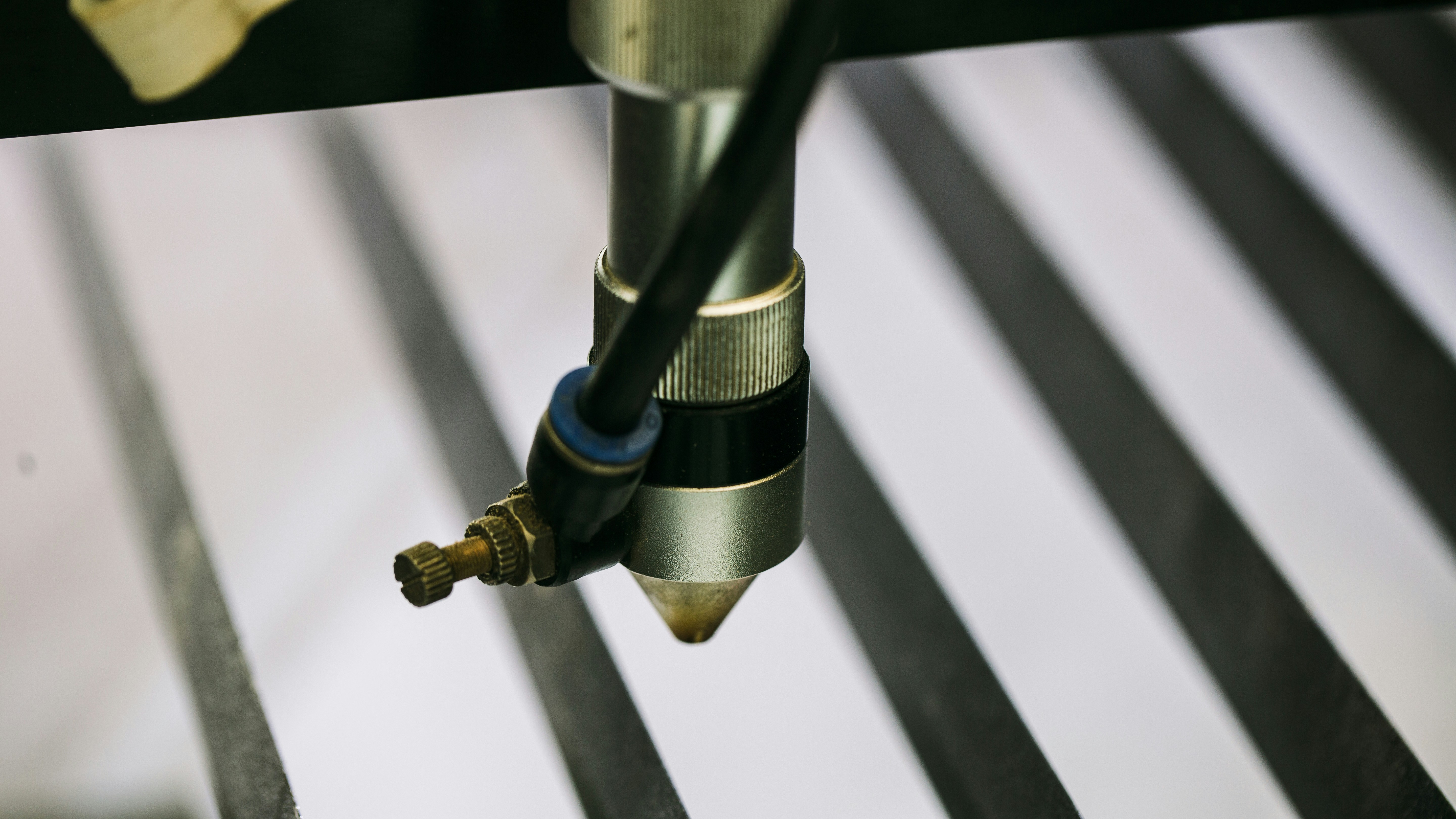

How Diamond Abrasive Filament is Made

The creation of diamond abrasive filament is a sophisticated manufacturing process that requires precise control over multiple variables. It transforms raw nylon resin and diamond powder into a high-performance abrasive tool through a multi-stage process. The quality of the final filament depends heavily on achieving a uniform distribution of diamond particles within the nylon matrix and extruding it to exact dimensional specifications.

The Infusion Process: Embedding Diamond in Nylon

The most common method for producing diamond abrasive filament is a process known as co-extrusion. This technique ensures that the diamond particles are not just coated on the surface but are integrated throughout the entire volume of the nylon filament.

- Compounding: The process begins with the careful selection of high-grade nylon polymer resin and precisely graded diamond powder. The diamond particles, which can be either monocrystalline (offering more cutting faces but more prone to fracture) or polycrystalline (more durable and self-sharpening), are blended with the nylon resin pellets. This blending is a critical step to ensure a homogenous mixture before melting. The concentration of diamond in the mixture, known as the abrasive loading, is carefully controlled to match the intended application of the filament.

- Extrusion: The compounded mixture is fed into an extruder. Inside the extruder's heated barrel, a rotating screw melts, mixes, and pressurizes the polymer-diamond blend. The molten material is forced through a die, a specialized tool with precisely machined holes, to form the continuous strands of filament. The temperature and pressure within the extruder must be meticulously controlled to ensure the nylon doesn't degrade and the diamond particles remain evenly suspended within the polymer matrix.

- Quenching and Drawing: As the hot filaments exit the die, they are rapidly cooled in a water bath, a process called quenching. This solidifies the nylon and locks the diamond particles in place. Following quenching, the filaments are often drawn or stretched. This drawing process elongates and orients the nylon polymer chains, which significantly increases the filament's tensile strength and stiffness.

- Spooling: Finally, the finished, dimensionally stable filament is wound onto spools, ready to be tufted into various brush constructions.

Filament Variations: Diameter and Grit Size

Diamond abrasive filaments are not a one-size-fits-all product. They are produced in a wide range of diameters and grit sizes to suit different tasks, from aggressive material removal to ultra-fine polishing.

Filament Diameter: The diameter of the filament typically ranges from around 0.3mm for fine, flexible applications to over 2mm for rigid, aggressive brushing.

- Thicker Filaments (e.g., >1.0mm): Offer greater stiffness and are used for heavy-duty tasks like aggressive deburring, edge radiusing, and removing heavy scale. They provide a faster cut but are less able to conform to intricate shapes.

- Thinner Filaments (e.g., <0.8mm): Provide more flexibility, allowing them to penetrate into complex geometries, internal passages, and follow contoured surfaces. They are ideal for light deburring, surface cleaning, and polishing where a fine finish is required.

Grit Size: The grit size refers to the size of the diamond particles embedded in the nylon. It is measured using a mesh scale, where a higher number corresponds to a smaller particle size and a finer finish.

The table below provides a general guide to selecting grit sizes for different applications:

| Grit Size (Mesh) | Particle Size | Typical Applications | Resulting Finish |

|---|---|---|---|

| 120 - 180 | Coarse | Aggressive deburring, heavy material removal, descaling | Rough, matte finish with visible scratch pattern |

| 240 - 320 | Medium | General-purpose deburring, edge blending, radiusing | Semi-matte, clean finish |

| 400 - 600 | Fine | Light deburring, surface cleaning, pre-polishing | Smooth, low-reflectivity finish |

| 800 - 1500 | Very Fine | Polishing, honing, final surface refinement | High-sheen, reflective finish |

| 2000 - 3000 | Ultra Fine | Superfinishing, lapping, optical-grade polishing | Mirror-like, flawless finish |

Choosing the correct combination of filament diameter and grit size is critical for achieving the desired outcome efficiently and economically.

Key Features of Diamond Abrasive Filament Brushes

The unique combination of diamond and nylon gives these brushes a set of key features that set them apart from conventional abrasive tools. These characteristics translate directly into enhanced performance, greater efficiency, and superior results in a wide variety of demanding industrial applications. Understanding these features helps in appreciating why they are often the preferred choice for challenging surface finishing tasks.

Superior Abrasive Performance with Diamond Abrasive Filament

The primary advantage of diamond abrasive filaments is their exceptional cutting performance. Because diamond is the hardest material available, it can abrade other hard substances with remarkable speed and efficiency. Unlike abrasives such as silicon carbide or aluminum oxide, which can dull when used on hardened steel or ceramics, diamond particles maintain their sharp cutting edges much longer. This results in a consistently high material removal rate, reducing cycle times in automated processes. Furthermore, this sustained cutting action ensures that the surface finish quality remains uniform from the beginning to the end of the brush's life, a critical factor for maintaining tight tolerances in precision manufacturing.

Enhanced Durability and Longevity of Diamond Abrasive Filament

Longevity is a hallmark of diamond abrasive brushes. This durability stems from two factors: the wear resistance of the diamond and the resilience of the nylon filament. The strong co-extrusion process ensures the diamond particles are securely locked within the nylon matrix, preventing premature grit loss. As the brush is used, the nylon tip wears away gradually, exposing new, sharp diamond particles. This self-sharpening action means the brush continues to cut effectively over a very long period. While the initial investment in a diamond brush may be higher than a conventional one, its extended lifespan often leads to a lower total cost of ownership due to reduced tool replacement frequency and less machine downtime.

Resistance to Chemicals and Temperature with Diamond Abrasive Filament

Industrial finishing is rarely a dry process. It often involves coolants, lubricants, and cleaning agents. Diamond abrasive brushes, particularly those made with high-grade Nylon 612, are engineered to withstand these harsh conditions. Nylon 612 has low moisture absorption and excellent resistance to a wide array of chemicals, oils, and solvents. This ensures the filament retains its stiffness and abrasive properties even when used in wet environments. Additionally, the material can tolerate the moderate temperatures generated during brushing operations without degrading, which is crucial for maintaining performance consistency and preventing damage to the workpiece.

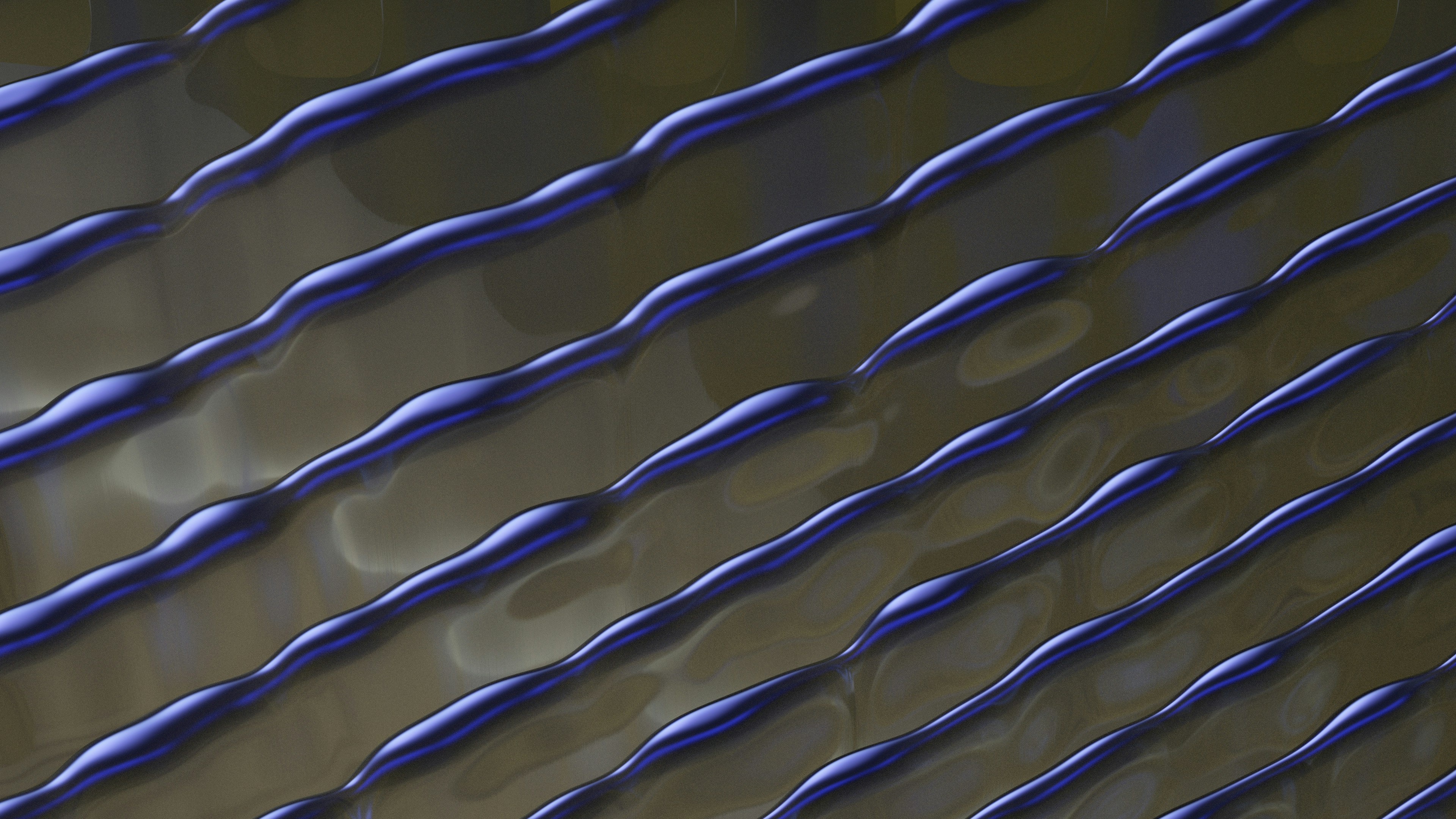

Versatile Design for Optimal Contact

To be effective, an abrasive must maintain consistent contact with the workpiece. Diamond abrasive filaments are tufted into various brush shapes and configurations to maximize this contact across different part geometries.

- Disc Brushes (or Wheel Brushes): These are ideal for finishing flat surfaces, deburring the faces of machined parts, or generating decorative finishes on stone slabs.

- Tube Brushes (or Radial Brushes): Designed with filaments pointing radially outwards, these are perfect for deburring the intersections of cross-drilled holes, cleaning internal passages, and finishing the inside diameters of cylinders.

- End Brushes: These are smaller, stem-mounted brushes used for spot-facing, cleaning mold cavities, and reaching into corners or tight spaces.

This design versatility, combined with the filament's flexibility, allows these brushes to effectively access and finish complex and contoured surfaces that are inaccessible to rigid grinding wheels or other fixed abrasives.

Applications of Diamond Abrasive Filament Brushes Across Industries

The unique properties of diamond abrasive filament brushes make them invaluable tools in a multitude of industries where precision, consistency, and performance on hard materials are paramount. From creating life-saving medical implants to finishing luxury automotive components, these brushes provide solutions for some of the most challenging surface finishing tasks.

Precision Finishing for Hard Materials with Diamond Abrasive Filament

The primary strength of diamond abrasives lies in their ability to machine materials that are too hard for conventional abrasives. This capability is critical in high-tech manufacturing sectors where advanced materials are the norm.

Honing and Deburring Carbide Tools

Tungsten carbide is an extremely hard and wear-resistant material used to make cutting tools, drills, and dies. After these tools are ground, they are often left with microscopic burrs and a sharp, brittle cutting edge. Diamond abrasive brushes are used to perform two critical tasks:

- Edge Honing: The flexible filaments gently sweep over the cutting edge, removing a precise amount of material to create a small, consistent radius. This honed edge is much stronger and less prone to chipping, which significantly extends the tool's life and improves its cutting performance.

- Deburring: The brushes effectively remove the fine burrs from flute gullets and cutting faces without damaging the primary cutting edge. This ensures cleaner cuts and better chip evacuation when the tool is in use.

Working with Glass, Ceramics, and Aerospace Alloys

- Glass and Ceramics: Technical ceramics (e.g., alumina, zirconia) and specialized glass are used in electronics, medical devices, and optics. After being machined or molded, they often have sharp edges or surface imperfections. Diamond abrasive brushes are used to smooth these edges, polish surfaces to a high sheen, and remove any micro-cracks that could lead to component failure.

- Aerospace Alloys: The aerospace industry relies on high-strength, temperature-resistant superalloys like Inconel, Hastelloy, and titanium. Machining these materials is notoriously difficult and often creates heavy burrs. Diamond abrasive brushes are essential for deburring critical components such as turbine blades, engine casings, and structural elements. Their ability to remove burrs without altering part geometry or introducing stress is vital for ensuring the safety and reliability of aircraft.

Surface Treatment and Polishing with Diamond Abrasive Filament

Beyond deburring hard materials, diamond abrasive brushes are also masters of surface texturing and polishing. They can be used to create both functional and aesthetically pleasing surfaces on a variety of materials.

Achieving Aesthetic Finishes on Stone

In the stone processing industry, diamond abrasive brushes are used to create popular "textured" finishes on granite, marble, and quartzite slabs. By varying the grit size and brushing parameters, fabricators can produce a range of appearances:

- Leathered Finish: Achieved with coarser grit brushes, this finish has a soft sheen and a pleasant, textured feel, similar to worn leather.

- Antiqued or Brushed Finish: This process uses brushes to texturize the stone surface, highlighting its natural structure and creating a rustic, aged look. The result is a non-reflective finish that is both beautiful and practical, as it helps to hide fingerprints and water spots.

General Surface Cleaning and Preparation

Diamond abrasive brushes are also excellent tools for preparing surfaces for subsequent processes like painting, plating, or coating. They can effectively remove oxides, heat-treat scale, and other surface contaminants from metal parts. Unlike aggressive grinding, the flexible filaments clean the surface thoroughly without removing significant amounts of the base material, preserving the part's dimensional integrity. This level of cleaning ensures better adhesion and a more durable final coating.

Industry-Specific Uses of Diamond Abrasive Filament

The versatility of these brushes is evident in their wide range of specialized applications across different sectors.

Automotive and Aerospace Components

The automotive and aerospace industries demand perfection in every component. Diamond abrasive brushes are used extensively to ensure the reliability and performance of critical parts.

- Automotive: They are used in automated cells to deburr transmission gears, smooth the surfaces of engine block cylinders, clean cross-drilled holes in crankshafts, and radius the edges of brake system components. Consistent deburring is essential for ensuring the smooth operation and long life of the drivetrain.

- Aerospace: As mentioned, they are indispensable for finishing jet engine components. They are used to deburr the fir-tree roots of turbine blades, polish airfoil surfaces to improve aerodynamic efficiency, and finish complex internal passages in fuel system components.

Optical and Jewelry Manufacturing

- Optical Industry: In the manufacturing of high-precision lenses and optical components, achieving a flawless surface is non-negotiable. Ultra-fine grit diamond abrasive brushes are used for polishing glass and other optical materials to a mirror finish, removing any microscopic scratches or defects that could distort light.

- Jewelry Manufacturing: Jewelers use fine-grit diamond filament brushes to polish precious metals like platinum and gold. The brushes can quickly bring a piece to a high luster, even on intricate designs, without causing the material loss associated with traditional polishing compounds and buffs. They are excellent for polishing detailed settings and cleaning up pieces after casting.

Choosing the Right Diamond Abrasive Filament Brush

Selecting the appropriate diamond abrasive brush is not just about picking one off the shelf; it's a technical decision that directly impacts the quality, efficiency, and cost-effectiveness of your finishing process. A brush that is perfect for one application may be completely unsuitable for another. Making the right choice requires a careful evaluation of the task at hand and an understanding of how different brush parameters influence performance.

Factors to Consider for Optimal Performance

To narrow down the options and find the perfect brush, consider the following critical factors. A systematic approach will ensure you match the tool to the specific demands of your workpiece and finishing goals.

| Factor | Key Considerations | Impact on Performance |

|---|---|---|

| 1. Workpiece Material | What is the material's hardness (e.g., aluminum, steel, carbide, ceramic)? Is it a ferrous or non-ferrous metal? | Harder materials require diamond abrasives. Softer materials like aluminum might perform better with silicon carbide to avoid excessive material removal. |

| 2. Task or Operation | Are you performing heavy deburring, light edge blending, surface cleaning, pre-polishing, or final polishing? | Heavy tasks require coarser grits and stiffer filaments. Polishing demands ultra-fine grits and more flexible filaments for a smooth finish. |

| 3. Grit Size | What surface finish (Ra) value are you trying to achieve? Do you need rapid material removal or a cosmetic, reflective finish? | Coarse grits (e.g., 120) remove material quickly but leave a rough finish. Fine grits (e.g., 1200) remove material slowly but produce a mirror-like finish. |

| 4. Filament Diameter | Does the brush need to be stiff for aggressive action or flexible to conform to complex shapes and internal bores? | Thicker filaments (e.g., 1.5mm) provide more aggressive action. Thinner filaments (e.g., 0.5mm) offer greater flexibility for contoured surfaces. |

| 5. Filament Density | Does the brush need a high filament density (more packed-in filaments) for a faster cut on flat surfaces, or a lower density for better compliance on irregular parts? | High density increases aggression and speeds up the process. Low density improves the brush's ability to conform to part geometry. |

| 6. Operating Speed (RPM) | What is the recommended peripheral speed for the brush diameter you are using? Are you running the brush too fast or too slow? | Running a brush too fast can cause the filaments to flare out and lose contact, while running it too slow reduces its cutting efficiency. |

| 7. Coolant Usage | Will the operation be performed dry or wet? If wet, is the nylon material compatible with the specific coolant or chemical being used? | Using a coolant almost always improves performance and extends brush life by reducing heat and clearing away swarf. Ensure chemical compatibility. |

Maximizing Brush Life and Efficiency with Diamond Abrasive Filament

Once you have selected the right brush, using it correctly is key to unlocking its full potential and ensuring a long, productive life. Adhering to best practices can significantly reduce your tooling costs and improve the consistency of your results.

- Adhere to Recommended Operating Parameters: Always consult the manufacturer's specifications for the optimal RPM and feed rate. Exceeding the maximum safe speed is not only dangerous but also counterproductive, as it causes the filaments to lose their effectiveness.

- Use Proper "Depth of Interference": Do not press the brush too hard into the workpiece. The ideal approach is to use a light touch, allowing just the tips of the filaments to do the work. Over-pressuring the brush causes the filaments to bend excessively, which reduces cutting action and leads to premature wear. A good rule of thumb is to set the interference depth to be no more than 10% of the filament's free trim length.

- Implement a Coolant: Whenever possible, use a steady flow of coolant. Coolant serves three vital functions: it reduces heat at the point of contact, it flushes away abrasive debris and swarf that can load the brush, and it lubricates the cutting action. This results in a better finish, faster cutting, and dramatically increased brush life.

- Periodically Reverse Direction: If your machinery allows, periodically reversing the direction of the brush's rotation can help to resharpen the filaments and extend the brush's useful life. This action helps to wear the filament tips evenly and expose new diamond cutting edges on all sides.

- Proper Storage: When not in use, store brushes in their original packaging or in a way that prevents the filaments from being bent, crushed, or contaminated. Damaged filaments will not perform correctly and can lead to inconsistent finishes.

By paying close attention to both selection and operation, users can transform diamond abrasive brushes from a simple tool into a highly reliable and efficient part of their manufacturing process.

Frequently Asked Questions (FAQ)

Q1: What is the main difference between diamond and silicon carbide abrasive brushes?

The primary difference is hardness. Diamond is significantly harder than silicon carbide (SiC). This makes diamond brushes far more effective and durable when working on very hard materials like tungsten carbide, ceramics, or hardened steel. Silicon carbide filaments are an excellent, more economical choice for working on softer, non-ferrous metals like aluminum, where diamond might be too aggressive. SiC filaments break down to expose new cutting edges, a property known as friability, which works well on such materials.

Q2: Can diamond abrasive brushes be used on soft materials like aluminum?

While they can be used, it's often not the ideal choice. Diamond's extreme hardness can cause it to remove material from soft metals like aluminum too quickly or even gouge the surface if not used with very fine grits and light pressure. For most aluminum deburring and finishing applications, a silicon carbide or aluminum oxide filament brush is more appropriate and cost-effective.

Q3: Do these brushes require a coolant?

While some applications can be done dry, using a coolant is highly recommended for most operations. A coolant dramatically improves performance by reducing heat, which prevents smearing on the workpiece and protects the nylon filament from thermal damage. It also flushes away swarf, keeping the abrasive sharp and preventing the brush from "loading." Using a coolant will almost always extend the brush's life and produce a better surface finish.

Q4: How do I know when to replace a diamond abrasive brush?

A diamond abrasive brush needs to be replaced when it no longer produces the desired surface finish or when its material removal rate has slowed down significantly. Visually, you can inspect the filaments. When they have become too short—typically when they have worn down by 50-75% of their original trim length—the brush has reached the end of its effective life. Continuing to use a worn brush will lead to inconsistent results and inefficiency.

Q5: What does "grit size" mean in a diamond filament?

Grit size refers to the size of the individual diamond particles embedded within the nylon filament. It is measured on a scale where higher numbers correspond to smaller particles. For example, a coarse 120-grit brush has large diamond particles and is used for aggressive material removal. An ultra-fine 1500-grit brush has very small particles and is used for polishing to a smooth, reflective finish. The choice of grit size is one of the most important factors in determining the final surface finish.

Conclusion

In conclusion, diamond abrasive filament in nylon brushes represents a significant advancement in abrasive technology. Their unique combination of diamond's aggressive cutting action and nylon's flexibility provides efficient and precise solutions for a vast array of challenging finishing problems that traditional methods struggle to address. From honing the cutting edges of carbide tools to creating beautiful textured finishes on natural stone, these brushes deliver unparalleled performance, durability, and versatility. As industries continue to push the boundaries of material science and demand ever-higher standards of quality and efficiency, these innovative tools, featuring advanced diamond abrasive filament, will undoubtedly play an even larger and more critical role in achieving superior results and enabling the manufacturing of next-generation products.